Existing Plant & Equipment

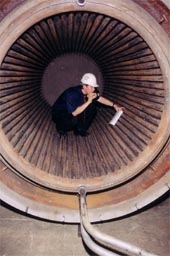

Enspec's unique familiarity with our client's processes and plant, combined with its broad-based experience of material failures, enables the preparation of a tailored inspection programme, which can accurately define What, Where, How and When to inspect.

This carefully targeted risk-based approach to inspection minimises plant downtime.

Enspec's personnel hold internationally-recognised qualifications required for the critical inspection of pressure vessels and other key plant items, as may be required by major insurance companies.

In any manufacturing environment, there are usually a number of key questions that need to be addressed at some point:

- What is the current condition of the existing plant?

- How can we reduce plant down time?

- Are we meeting the required safety standards within the company?

- Can we reduce the environmental impact of the plant?

- How can we reduce our plant maintenance costs?

New Plant & Equipment

Enspec has developed a fabrication monitoring service that can be tailor-made for any manufactured item. The role of the insurance agency in a particular country can be somewhat limited to the supervision of the key stages of construction, in accordance with the construction code requirements.

Enspec's role is therefore to address matters of overall future reliability, based on past experience, in areas such as fatigue cracking, corrosion or material degradation. It is a fact that a large number of failures occur as a result of a defect initiating at a non-critical part in the construction. It is these areas that are often overlooked during construction, as they would not normally fall within the scope of the statutory inspection requirements.

Enspec provides a specialist technical support service to cover fabrication details, ranging from material selection to design detail, through to quality of execution, all of which would be incorporated into a quality improvement plan.