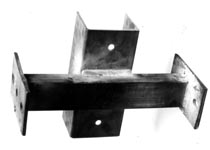

Figure 1.

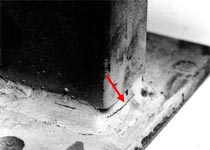

Figure 2.

Figure 3.

Background

As part of a major expansion project, a client had ordered a new racking system designed for operation at temperatures down to -28°C. It was a 30 bay drive-in system design with welded horizontal beam connectors which were bolted to the main columns. The columns were fixed to the concrete floor by means of welded foot plates.

In this particular case, Enspec were requested to review the manufacturing procedures for the racking prior to construction. In order to ensure a good standard of welding would be achieved, Enspec requested that a number of welded test pieces be prepared prior to construction.

Findings

Although the system was essentially of a bolted design, it incorporated a limited amount of welding between some of the critical components. During the course of the preparation of the test pieces, it became apparent that there were a number of shortcomings with respect to the welding procedures. The test pieces were found to contain a number of weld-related defects that were not considered to be acceptable i.e.

- Weld centreline cracking in the beam connector brackets (figures1 and 2 - arrowed).

- Incomplete fusion between the foot plate to upright column fillet welds.

The welding and fabrication procedures were subsequently modified to ensure cleanliness of all the structural, components prior to welding.

Key Point

- Like other plant and equipment items of high value, new racking installations need to be inspected independently during construction and installation, to ensure conformity with the design and fabrication code criteria.